In the intricate world of mechanical maintenance and automotive care, the significance of specialty cleaning often goes underappreciated. Yet, it stands as a cornerstone for ensuring the peak performance and extended lifespan of various machines and vehicles. From the precise bearings that facilitate smooth operations of machinery to the robust engines of motorcycles, each component demands a unique approach to cleaning and maintenance. This article delves into the nuanced realm of specialty cleaning, shedding light on its critical role in both everyday and specialized mechanical contexts.

Navigating through the labyrinth of cleaning products, tools, and techniques can be daunting. Whether it’s choosing the right solvent for cleaning bearings or selecting an air cleaner that enhances the performance of a Harley Davidson, the choices made can have profound impacts on functionality and efficiency. This comprehensive guide is designed to walk you through the various aspects of specialty cleaning, from understanding the basics to exploring advanced methods and safety practices.

What is Specialty Cleaning?

Specialty cleaning refers to the detailed and often technical process of cleaning specialized equipment, machines, or environments. Unlike routine cleaning, specialty cleaning requires specific tools, chemicals, and methods tailored to the item or area being cleaned. This type of cleaning is often essential in industries where precision and cleanliness are critical, such as healthcare, manufacturing, aerospace, and automotive sectors.

The Scope of Specialty Cleaning

The realm of specialty cleaning is vast and diverse, covering a broad spectrum of applications. Some key areas include:

- Industrial Cleaning: Involving the cleaning of machinery, warehouses, and industrial equipment. This type of cleaning is crucial for maintaining equipment efficiency and preventing malfunctions or failures.

- Medical and Healthcare Cleaning: Focused on sterilizing and disinfecting medical equipment and facilities to prevent the spread of infections and ensure patient safety.

- Automotive Cleaning: Specialized cleaning of automotive parts, such as engines, air filters, and bearings, to ensure optimal performance and longevity.

- Electronics and Cleanroom Cleaning: Involves cleaning in environments where even microscopic dust particles can cause significant damage or contamination, such as in semiconductor manufacturing or laboratory settings.

- Environmental and Hazardous Material Cleaning: Dealing with the removal and disposal of hazardous substances while ensuring compliance with environmental regulations.

General Cleaning vs. Specialty Cleaning: Key Differences

Understanding the distinction between general and specialty cleaning is crucial for grasping the importance and intricacies of the latter. Here are some key differences:

- Purpose and Precision: General cleaning focuses on maintaining a clean and hygienic environment, primarily for aesthetic and basic health reasons. Specialty cleaning, on the other hand, is often centered around the operational integrity and safety of specific equipment or environments. It requires a higher degree of precision and attention to detail.

- Tools and Products: While general cleaning can be accomplished with common cleaning products and tools, specialty cleaning often requires specialized equipment, chemicals, and techniques. For instance, cleaning a pharmaceutical lab involves different products and standards than cleaning a typical office space.

- Training and Expertise: Specialty cleaning typically demands a higher level of training and expertise. Professionals engaged in specialty cleaning must have a deep understanding of the materials, equipment, and safety protocols relevant to their specific field.

- Regulatory Compliance: Many specialty cleaning tasks are governed by strict regulatory standards, particularly in industries like healthcare, food processing, and manufacturing. Compliance with these regulations is crucial to ensure safety and avoid legal ramifications.

- Frequency and Methodology: The frequency and method of specialty cleaning can vary significantly from general cleaning. Some specialty cleaning tasks may be performed less frequently but require a more thorough and methodical approach.

What Are Bearings?

Bearings are mechanical components that limit relative motion to only the desired motion and reduce friction between moving parts. Essentially, they support rotating parts and help in the smooth transfer of motion.

The Role of Bearings in Machinery

Bearings are pivotal in various applications. They are found in everything from automotive engines to wind turbines. Their primary roles include:

- Reducing Friction: Bearings facilitate smoother motion of machinery parts, thereby reducing friction and wear.

- Supporting Loads: They bear the burden of loads, ensuring that machinery can operate under various weight conditions.

- Enhancing Performance: By reducing friction, bearings contribute to the efficiency and performance of machinery, extending its lifespan.

Importance of Regular Maintenance

Regular maintenance of bearings is vital to prevent breakdowns and extend the life of machinery. Dirt, debris, and wear can significantly impact their performance.

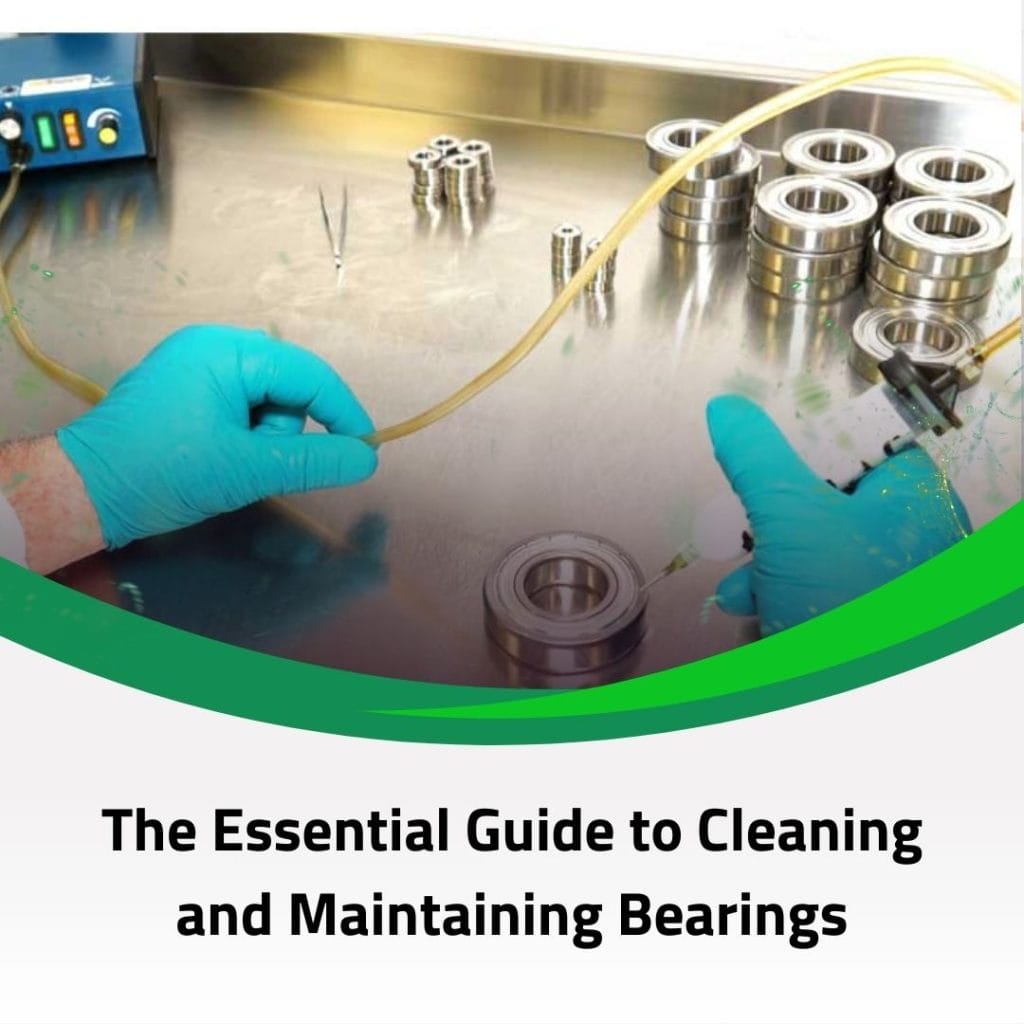

Steps for Cleaning and Maintaining Bearings

Disassembly: Carefully disassemble the bearing components.

Inspection: Examine bearings for signs of wear or damage.

Cleaning: Use appropriate solvents to clean the bearings.

Lubrication: Apply suitable lubricants after cleaning.

Reassembly: Reassemble the bearings with care, ensuring they are properly aligned.

Best Cleaning Solvents for Bearings

When it comes to cleaning bearings, choosing the right solvent is crucial. The best solvents are effective in removing grease, dirt, and debris without damaging the bearing material.

Top Solvent Choices

Isopropyl Alcohol: Ideal for degreasing and drying quickly.

Acetone: Effective in removing heavy grease but must be used with care due to its strong nature.

Petroleum-Based Solvents: Good for heavy-duty cleaning but require proper handling due to their flammable nature.

Factors to Consider in Solvent Selection

- Compatibility: Ensure the solvent does not corrode or damage the bearing material.

- Safety: Consider the safety aspects, including flammability and toxicity.

- Environmental Impact: Choose solvents that are environmentally friendly and dispose of them responsibly.

The Importance of Cleaning for Motorcycle Performance and Maintenance

Preserving Engine Health

The engine is the heart of the motorcycle. Regular cleaning of the engine and its components prevents the build-up of dirt and grime, which can lead to overheating, reduced efficiency, and even long-term damage.

Enhancing Aesthetics and Value

A well-maintained motorcycle not only looks better but also retains more value. Regular cleaning protects the bike from corrosion, rust, and wear, ensuring it stays in pristine condition.

Safety Considerations

Dirt and debris on critical components like brakes and tires can compromise the safety of the motorcycle. Through specialty cleaning, these risks are significantly reduced.

Why Focus on Air Cleaners?

Air cleaners play a crucial role in motorcycle performance. They are responsible for ensuring that clean air enters the engine for combustion, a process vital for the efficient running of the bike.

Impact of Air Cleaners on Performance

- Optimized Fuel Efficiency: A clean air filter ensures a proper air-fuel mixture, leading to better fuel efficiency.

- Increased Engine Power: Clean air filters allow for optimal air flow, which is crucial for maintaining engine power and responsiveness.

- Reduced Engine Wear: By filtering out harmful particles and debris, air cleaners protect the engine from premature wear and tear.

Signs of a Dirty Air Cleaner

- Reduced acceleration and power.

- Unusual engine noises.

- Decreased fuel efficiency.

- Visible dirt and clogging in the air filter.

Maintaining Air Cleaners

Regular Inspection and Cleaning

- Check the air cleaner regularly, especially when riding in dusty or dirty environments.

- Clean the air cleaner as per the manufacturer’s guidelines. This could involve blowing out dust or washing a reusable filter.

Replacement When Necessary

- Air cleaners should be replaced according to the maintenance schedule provided by the motorcycle manufacturer, or sooner if they show signs of excessive wear.

Choosing the Right Air Cleaner

- Select an air cleaner that is compatible with your motorcycle model.

- Consider high-quality aftermarket options for enhanced performance and longevity.

Cleaning Tools and Products

With advancements in technology and a growing awareness of the need for effective and efficient cleaning, a variety of specialized tools and products have emerged. These innovations not only streamline the cleaning process but also ensure a level of cleanliness that standard tools can’t match.

High-Tech Cleaning Gadgets

Robotic Vacuum Cleaners

- Function: Automated vacuuming of floors and carpets.

- Advantages: Time-saving, efficient, and ideal for maintaining daily cleanliness with minimal effort.

Ultrasonic Cleaners

- Function: Using ultrasonic waves to clean delicate items like jewelry, eyeglasses, and small mechanical parts.

- Advantages: Deep cleaning at a microscopic level, gentle on items, and effective in removing stubborn dirt and grime.

Steam Cleaners

- Function: Utilizing hot steam for cleaning and sanitizing surfaces.

- Advantages: Chemical-free cleaning, effective in killing bacteria and allergens, and versatile for various surfaces.

Specialized Cleaning Solutions

Eco-Friendly Cleaning Agents

- Purpose: Offer a sustainable alternative to traditional cleaning chemicals.

- Benefits: Safe for the environment, non-toxic, and often biodegradable.

Heavy-Duty Degreasers

- Purpose: Tackle tough grease and oil stains, commonly used in industrial and automotive settings.

- Benefits: Powerful cleaning action, suitable for machinery and automotive parts.

Hypoallergenic Cleaners

- Purpose: Designed for environments where occupants may be sensitive to allergens and harsh chemicals.

- Benefits: Minimize the risk of allergic reactions, safe for use in homes, schools, and healthcare facilities.

Innovative Cleaning Accessories

Microfiber Cloths

- Use: For dusting and cleaning surfaces without leaving streaks or lint.

- Advantages: Highly absorbent, reusable, and effective in trapping dirt and dust.

Telescopic Cleaning Brushes

- Use: To clean hard-to-reach areas like high windows, ceilings, and light fixtures.

- Advantages: Extendable handles, versatile use, and reduces the need for ladders or step stools.

Electric Scrub Brushes

- Use: For deep cleaning of tiles, grout, and other textured surfaces.

- Advantages: Saves manual labor, enhances cleaning efficiency, and offers consistent results.

Safety Practices in Specialty Cleaning:

In the specialized field of cleaning, particularly when dealing with potent solvents and cleaning agents, safety cannot be overstated. The use of these substances, while effective for cleaning and maintenance, comes with inherent risks. This article underscores the importance of safety in the use of solvents and cleaning agents and outlines best practices to ensure a safe cleaning process.

The Importance of Safety in Using Solvents and Cleaning Agents

Health Risks and Hazards

- Toxicity: Many solvents and cleaning agents contain chemicals that can be toxic if inhaled or ingested.

- Skin and Eye Irritation: Direct contact with skin or eyes can lead to irritation, burns, or allergic reactions.

- Fire and Explosion Hazards: Some solvents are highly flammable and pose risks of fire or explosions.

Environmental Concerns

- Pollution: Improper disposal of solvents can lead to environmental pollution, affecting soil and water quality.

- Air Quality: Volatile organic compounds (VOCs) in some solvents contribute to air pollution and pose health risks.

Best Practices for Safe Cleaning

Personal Protective Equipment (PPE)

- Use of Gloves: Protect hands from direct contact with cleaning agents.

- Safety Goggles: Prevent splashes from entering eyes.

- Respiratory Protection: Use masks or respirators in well-ventilated areas to avoid inhaling fumes.

Proper Ventilation

- Adequate Airflow: Ensure cleaning is done in well-ventilated areas to dissipate fumes.

- Use of Exhaust Fans: Helpful in enclosed spaces to maintain air quality.

Safe Handling and Storage

- Labeling and Storage: Clearly label all containers and store them in a cool, dry place away from heat sources.

- Spill Management: Have spill containment and cleanup procedures in place.

Training and Awareness

- Knowledge of Material Safety Data Sheets (MSDS): Understand the properties and hazards of the chemicals being used.

- Training in Safe Handling: Regular training sessions for anyone using these chemicals.

Responsible Disposal

- Follow Local Regulations: Dispose of solvents and cleaning agents as per local environmental regulations.

- Recycling and Reuse: Explore options for recycling or reusing cleaning agents to minimize waste.

Use of Eco-Friendly and Safer Alternatives

- Exploring Alternatives: Whenever possible, use eco-friendly or less hazardous cleaning agents.

Enhancing Performance through Cleaning

Whether it’s industrial equipment, household appliances, or automotive parts, regular and proper cleaning is not just a matter of appearance—it’s a crucial factor in enhancing performance and extending lifespan. Neglecting this vital aspect can lead to decreased efficiency, higher running costs, and even premature failure. This article delves into how regular and diligent cleaning can markedly improve the performance and longevity of various types of machinery.

The Impact of Cleaning on Machinery Performance

Preventing Build-Up of Dirt and Debris

- Issue: Accumulation of dirt, dust, and debris can impede the functionality of machinery, leading to overheating and increased wear.

- Solution: Regular cleaning prevents this build-up, ensuring that machinery operates within optimal temperature ranges and without unnecessary strain.

Maintaining Efficiency and Energy Usage

- Issue: Unclean machinery often requires more energy to perform its tasks, leading to inefficiency and increased operational costs.

- Solution: Clean machinery operates more efficiently, uses less energy, and thus reduces operational costs over time.

Avoiding Corrosion and Wear

- Issue: Dirt and moisture can lead to rust and corrosion, particularly in metal components, shortening the lifespan of machinery.

- Solution: Regular cleaning and proper maintenance routines help to prevent corrosion, thereby extending the lifespan of machinery.

Best Practices for Machinery Cleaning

Regular Cleaning Schedules

- Implementing a regular cleaning schedule is vital. Depending on the machinery type and usage, this could range from daily to monthly cleaning.

Using the Right Cleaning Tools and Products

- Selecting appropriate cleaning tools and products is crucial. For instance, using non-abrasive cleaners on sensitive components can prevent damage.

Professional Maintenance and Cleaning

- For complex machinery, professional maintenance and cleaning may be necessary to ensure all components are properly and safely cleaned.

The Future of Specialty Cleaning: Emerging Trends and Eco-Friendly Innovations

The specialty cleaning industry is on the cusp of a transformative era, marked by rapid advancements in technology and a growing emphasis on environmental sustainability. As we look to the future, it’s clear that the ways we approach specialty cleaning are evolving, driven by innovation and a deeper understanding of our environmental impact. This article explores the emerging trends and technologies in specialty cleaning, alongside the shift towards eco-friendly solutions and practices.

Emerging Trends and Technologies in Specialty Cleaning

Automation and Robotics

- Robotic Cleaners: Advancements in robotics have led to the development of automated cleaning systems, capable of performing complex cleaning tasks with minimal human intervention.

- Smart Technology: Integration of IoT (Internet of Things) in cleaning equipment, allowing for remote monitoring, operation, and data analysis to optimize cleaning processes.

Advanced Filtration Systems

- HEPA Filters: High-Efficiency Particulate Air (HEPA) filters are becoming more common in specialty cleaning, trapping airborne particles more effectively than traditional filters.

- Water Filtration Technologies: Innovations in water filtration for cleaning purposes, reducing water waste and improving cleaning efficiency.

Green Chemicals and Solvents

- Bio-Based Solvents: Development of solvents derived from renewable resources that are less toxic and more biodegradable.

- Reduced VOCs: Focus on reducing volatile organic compounds in cleaning products to improve indoor air quality and reduce environmental impact.

Nanotechnology

- Nano-Coatings: Application of nanotechnology in protective coatings, making surfaces more resistant to dirt and easier to clean.

- Nano-Scale Cleaning Solutions: Utilizing nanotechnology for deeper and more efficient cleaning at the microscopic level.

Environmental Considerations and Eco-Friendly Cleaning Solutions

Sustainable Practices

- Reduced Chemical Usage: Emphasis on cleaning practices that minimize the use of harsh chemicals, reducing environmental pollution.

- Water Conservation: Innovations aimed at reducing water usage in cleaning processes, crucial in areas facing water scarcity.

Eco-Friendly Products

- Plant-Based Cleaners: Growth in the use of cleaners made from plant-derived ingredients, offering a safer and more sustainable alternative to synthetic chemicals.

- Biodegradable Packaging: Shift towards packaging made from biodegradable materials to reduce plastic waste.

Environmental Certification and Compliance

- Green Certifications: Increase in products and services that meet strict environmental standards and certifications.

- Regulatory Compliance: Adherence to environmental regulations and guidelines in the use of cleaning agents and practices.

Conclusion

Navigating the complex and diverse world of specialty cleaning, particularly in the context of bearings and motorcycles, reveals a multifaceted landscape that intertwines technical expertise, safety considerations, environmental consciousness, and technological advancements. From the intricate role of bearings in machinery, demanding specific cleaning and maintenance practices, to the nuanced needs of motorcycle maintenance with a focus on air cleaners, each aspect underscores the importance of specialized cleaning approaches.

We delved into the realm of advanced cleaning tools and products, highlighting how technological innovations and eco-friendly solutions are reshaping the industry. The emphasis on safety practices, especially when handling solvents and other cleaning agents, reflects a growing awareness of the health and environmental implications of specialty cleaning.

Looking to the future, we see a trend towards automation, advanced filtration, and green chemicals, pointing to an era where efficiency and sustainability coexist. This evolution in specialty cleaning practices not only enhances performance and prolongs the lifespan of machinery but also aligns with a broader commitment to environmental stewardship.